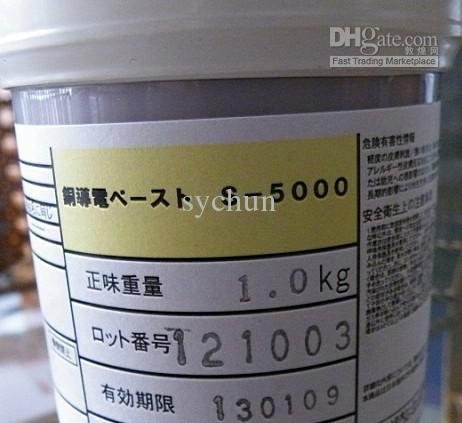

Conductive copper paste

Model No.︰S5000

Brand Name︰-

Country of Origin︰Japan

Unit Price︰US $ 668 / kg

Minimum Order︰1 kg

Product Description

S5000 series polymer conductive copper paste is a Japanese Mitsui Corp R & D, spherical and flaky silver, precious metals and copper nanostructures, electrical conductivity, strong anti oxidation and anti high temperature capability, the thermosetting resin do organic carrier developed electronic paste.Is a fully applicable to the copper process component, can be directly welded to the conductive copper paste, applies SMD technology and multilayer connecting point of each printing, printed after the screen on the excess copper slurry can be put into the packing bottle for use next time.

Scope of application: S5000 is especially suitable for multi-layer circuit board printing, welding, solar cell pads etc..

S5000 and lithographic printing compared to lower cost, is reflected in the:

L natural drying or low temperature of 130 degrees, and bake for 30 minutes.

2 surface does not require nitrogen fixation treatment.

3 through the hot air leveling or hand welding repair, has excellent adhesion

4 can be directly solder, use as electrode.

In two, the main character:

Component component

Surface electric resistance ≤ 5X10-4ohm.cm (30 microns thickness)

The color gray brown

Solvent resistance MEK

Welding temperature: 300 °

Three, product use: mainly used for membrane switch, flexible circuit, circuit boards and other electronic fields.

Application of the substrate:

In PCB, PET, PVC, copperplate paper, resin, metal, glass and other substrates for use, has excellent adhesion.

Basic quality parameters:

Name of low-temperature copper paste type S-5000

Storage temperature of 0~5 ℃ low temperature storage

The appearance of grey brown viscous slurry, no impurities, no crust, no delamination

Viscosity (Pa.s) 500+100

Density of 25 ℃ kg/L 4.1 ± 0.3

Solid content (%) 80 ± 1

Adhesion of kg/mm2 ≥ 0.8

The density of kg/L ≈ 2 kg

The pencil pencil hardness: ≥ 2H

Drying conditions of 160 ℃, 30min

Application of the substrate PET, PVC, copperplate paper, resin, metal, glass and other materials

Stencil cleaning agent ethyl acetate, cyclohexanone, isopropyl alcohol.

Product Image